Deciding on composite decking boards? You need to know that not all composites are of the same quality! Find out the difference between PVC based composites and those based on PP and HDPE. Before buying, make sure which product is the most suitable for your terrace.

WPC composite - what exactly is it?

In the construction market composites are known under the acronym WPC. It comes from the English language and means wood plastic composite. In fact, a composite material usually consists of at least two components - a so-called matrix which is a plastic material and wood particles. In the manufacturing process, the composite materials are combined under high pressure and temperature to form a homogeneous mass. Basically, this is where the similarity of composite materials ends. There are a number of differences that affect durability, resistance to changing climatic conditions and appearance.

The main difference is the type of warp used in composite boards. This matrix can consist of polyvinyl chloride (PVC), polypropylene (PP) and polyethylene (PE or HDPE). The latter two materials are often designated as polyolefins; unlike PVC, they are products derived from petroleum refining.

Which composite material is worth choosing?

The aforementioned differences in materials from which composite boards are made have an impact on their significant usability and durability. They originate from the characteristics of the polymers, which were used as the matrix of the composite material. Below we present the main differences in physical and mechanical properties of particular polymers, which are inherited by the final composite product made with their use.

The presented comparison clearly shows that in each of the parameters the PVC-based matrix wins decisively. This material is harder, more resistant to destruction, undergoes significantly less deformation under the influence of changing weather conditions (temperature changes) and does not spread fire.

PVC guarantees terrace durability in the European climate zone!

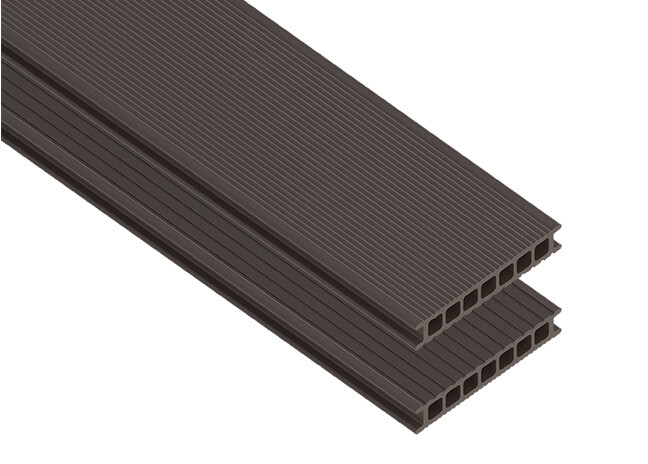

PVC composite boards due to their high resistance, exceptional surface hardness and ease of maintenance are a well-known terrace material used in the construction industry for many years. They are characterized by low abrasiveness - they are resistant to scratches and mechanical damage, they do not absorb moisture and thus do not crumble over the years. Their high resistance to UV radiation means that they do not fade or soften under its influence, and the polymerization process used in their production ensures their strength at low temperatures.

Unlike PVC based composites, PP and HDPE boards are easier to scratch even when used lightly. Their reduced density makes them significantly less resistant to low temperatures. They are also highly susceptible to changes in weather conditions and sunlight - under their influence they deform relatively more easily, crumble, and lose their color. Due to their inherent "softness", their surface is usually sanded or smooth. PVC-based composite boards in order to give them a texture similar to wood have a brushed surface, which reduces their slipperiness, and to the touch creates a pleasant feeling of contact with natural wood.

European manufacturers - safety and protection for the user!

Composites based on polypropylene and polyethylene usually come from countries in the Far East. They are often offered by manufacturers who are not bound by the strict legal restrictions applied by European manufacturers. As a result, the offered products do not have the features of construction products, they are often devoid of hygienic certificates, and their sale is driven by their low price, not the real utility value.

PVC boards have a fire resistance class B defined on the basis of EU standards - indicating non-flammability, in contrast to products containing polymers of reduced durability, which are characterized by fire spreading. PVC-based composite decking is also 100% renewable, which contributes more to environmental protection. Their physical-mechanical properties guarantee a longer useful life, and they do not emit any harmful substances into the environment.

Opt for timeless terrace style and elegance combined with durability!

Due to the presence of petroleum derivatives composite boards basing on PP, PE and HDPE pose a risk of safe use, and the increased content of wood materials reduces their durability. Often after just a few seasons, visible deformation of their working surface can be observed. Planks made of low-grade polymers are also susceptible to color changes and easy to rub off.

The secret to the appearance of composite wood is the properly selected proportions of wood dust in relation to the other components, as well as the high quality materials used in their production. Proper sanding methods prove the hardness of the material, ensuring that composites are safe and non-slip. Thanks to the care given to the quality of PVC boards, they retain their shape and durability and enjoy their beauty for years.

Telling the difference between "poor" and high grade decking.

1. Price.

PP and HDPE composites are widely available at lower prices than PVC composite decking. This difference is due to the significantly higher cost of PVC compared to polyolefin matrix prices. An additional factor affecting the price is the cost of production. Manufacturing PVC composite, due to its increased hardness and temperature resistance, requires more energy.

2. Board dimensions.

Price is not the only determinant of PVC composites. As mentioned earlier, composite boards made from polyolefins are mainly imported. In order to facilitate transportation (which is usually done in sea containers), these boards are usually shorter than the production standard in Europe. Their length is about 2.5 m and results from the selection of dimensions with a view to optimizing transport costs.

3. Appearance.

Boards made on the basis of polyolefins have thicker, more massive walls. This is necessary because polyolefin composites are inherently less resistant to bending and pressure. In order for them to meet the required resistance parameters, it is necessary to increase the amount of material contained in the board. This allows the board to have the required strength, but does not improve its resistance to weathering and surface degeneration. It is also worth finding out the maximum spacing of the joists recommended by the supplier. The more flabby the composite decking is, the more densely it should be supported by joists. PVC composite boards are supported every 50 cm as a standard. In the case of composites based on PP, PE and HDPE this distance is often limited to about 30 cm. This means that almost twice as many joists and fasteners (clips and screws) are required per meter of terrace width.

4. Smell.

Boards made of polyolefin have an odour commonly associated with plastics. Sometimes their composition is supplemented with aromatic substances who are aimed on neutralization of unfavorable scent experiences of their users. The smell of the decking becomes stronger especially when they are heated up in the sun. In addition, during the cutting of the boards the polyolefin warp may be melted due to friction and may adhere to the sides of the saw blade. In the oposite PVC-based composite decking have a natural wood smell, which is noticeable mainly after cutting, on the edges of freshly cut boards. They do not emit any unnatural odours, nor do they irritate the smell, even when heated to high temperatures. During cutting they behave like natural wood without leaving any traces on cutting tools.

5. Technical and quality documentation.

As a standard, the products approved for use in construction are provided with documentation including a technical approval. This document is issued by an accredited national or European unit (e.g. Institute of Building Technology) and specifies, among other things, the basic physical and mechanical parameters of a construction product. It also contains the manufacturer's designation and a list of basic components of the product. Most imported composite boards are not subjected to the rigors of construction assessment and, in principle, should not be used as a construction product. An additional element that helps to determine the reputation of the product is the fire resistance classification and hygienic certificate. In contrast to PVC composite boards, polyolefin-based composites are not able to achieve in tests the parameters allowing them to be classified as non-flammable materials (class B). Their fire resistance class is C, which means that they are inflammable and spread fire.